FISHING INDUSTRY

Flake ice keeps fish and shellfish perfectly cool, making easier the subsequent handling (filleting, etc.). Thanks to its important cold inertia, it is particularly suitable for these products as it allows them to cool quickly.

Flake ice allows fish to be cooled as soon as it is caught at the sea or selected (in the case of fish farms), without breaking the cold chain during processing, transport and final sale, considerably prolonging its shelf life and making it perfect for storage.

When ice is placed on the fish, the heat from the fish flows into the ice and melts it. The cold melt water absorbs the heat from the fish and as it flows over the ice, it cools again, preventing it from drying out, avoiding weight loss, stopping the development of microorganisms that lead to deterioration and maintaining its natural moisture.

In the case of fish farms, flake ice has specific functions: to anesthetize the fish by cold shock (water/ice mixture) to limit stress conditions and their influence on the characteristics of the meat; to control their temperature during rigor mortis phase before handling; etc…

For all these reasons, fish keeps its nutritional qualities as is maintained at an ideal temperature throughout all stages.

INESA has an extensive experience in the production, storage, distribution and weighing of ice in the fishing sector thanks to our generators and silos of different capacities: ships, fishing ports, fish wholesalers, fish auctions, fishermen’s cooperatives, public wholesale fresh food markets (Mercas), ice sellers, fish processing industries, fish farms, canning industry, etc.

Throughout its history, INESA has realized hundreds of installations for the production of flake ice both on land, using fresh water, and on board fishing vessels, using salt water. Thanks to that, the crew can produce their own ice on board independently. Our company has equipped a large part of the Spanish fishing fleet.

Dam in RCC in Enciso (La Rioja)

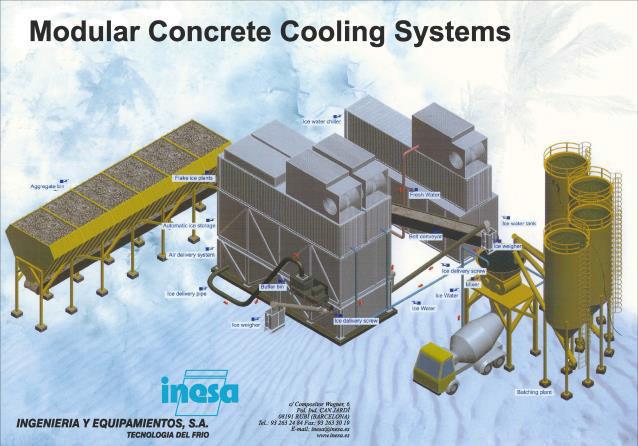

CONCRETE COOLING

In the last twenty years, INESA has specialized in the cooling of concrete, carrying out ad hoc projects in large-scale civil works (dams, hydroelectric power plants, highways, bridges, etc.).

For more information, visit the Product section.

Each project is different as it adapts to the specific needs of the client as well as the weather conditions of the area where the project is located. The same technique is not required for cooling the concrete up to 8 ºC for a hydroelectric power station as for cooling the concrete up to 25 ºC for any other civil works project.

Depending on the characteristics of the project, INESA will propose to the client the best way to carry out the cooling of the concrete, resorting to one or more techniques that will require the following equipments:

– Ice maker and ice storage silo

– Water coolers

– Air coolers

Dam in Daivões-Iberdrola (Portugal)

I+D+I

Since its beginning, INESA has been interested in researching, developing new products, and innovating in designs to provide the best response to the needs of our customers.

- DEVELOPMENT OF ORBITAL SILOS

INESA has responded to the need for ice storage with automatic discharge by developing orbital silos with automated flat-bottom discharge systems that offer significant advantages compared with other ice storage and discharge methods. Among them, the reduction of labor costs while achieving an efficient and constant ice flow with high discharge rates.

Our silos form a closed storage system that eliminates ice contamination and losses due to caking and formation of blocks that are difficult to remove.

Our silos present two versions, one made of AISI 304 stainless steel, easy to assemble in existing cold rooms, and another made of food polyester reinforced with fiberglass compatible with EU regulation on food products.

For more information, visit the Products section.

Stainless steel Silo

Polyester Silo

- DESIGN OF FLOW ICE MAKERS

We have developed a shell ice generator called AVALANCHA®. This ice factory has the great energetic advantage of producing ice of controllable thickness with an evaporation temperature of -10 º, which allows it to work with a very high coefficient of performance (COP). This characteristic makes it especially suitable for saving energy by storing ice with night rate and thus being able for air-conditioning of hotels, hospitals, shopping centers, office buildings, university centers, etc. with quality air-conditioning and low energy cost.

Secondly, INESA has expanded the capabilities of its AVALANCHA® ice factory, making it polyvalent since it can also produce liquid ice with the same structure. This new version uses liquid ice to clean pipe installations with calcareous or other deposits. This technique is known as ICE PIGGING.

For more information, visit the Products section.

- STUDY OF NEW ICE APPLICATIONS

- IMPROVEMENT OF ICE FACTORIES PERFORMANCE

- ANALYSIS OF POSSIBILITIES FOR CHILLED WATER OR ICE STORAGE

- ETC…

FOOD DISTRIBUTION

INESA has installed in Spain hundreds of ice factories in Hypermarkets, Supermarkets and large fishmongers.

Products retain all their flavour and freshness from the high seas. In the case of flake ice, as it is a sub-cooled product, keeps the fish fresher for a longer period of time.

Ice is produced overnight and, thanks to the orbital silo and the conveyer, reaches the shop counter easily and without handling. Therefore, the time for preparing fish display in the counter is greatly reduced.

Lack of ice damages seriously the quality of fresh and fragile products such as fish, so ice is added throughout the day to compensate for melting ice.

In large retail areas, ice is widely used as it is a key element for the presentation of the product to the end consumer. Thanks to its shining whiteness, it provides a natural environment and increases the value of the product. Consumers appreciate seeing fresh and shiny fish wrapped in flake ice as part of the purchasing experience.

INDUSTRIAL BAKERY

In the kneading process, the dough used for the industrial manufacturing of bread as well as pastry and confectionery (cakes, pastries, cookies, etc.) is heated. The heat input due to the mechanical work done by the mixer makes it necessary to cool the kneading water that enters the dough composition.

The addition of flake ice allows the control of the water temperature, counteracts and prevents an excessive increase of degrees. It is especially useful when the bakeries or the flour itself temperature is high, or when the kneading is intensive (long duration and fast speed).

The very structure of flake ice, flat and thin, allows it to melt in the dough without leaving residues. On the other hand, granular ice can cause problems in the baking process as it can remain without melting and this can lead to air pockets inside the product.

The temperature of the dough leaving the mixer must reach a temperature of 22 to 25ºC to avoid secondary fermentation. Flake ice helps to delay the yeast growth, allowing to control the dough within the required times.

MEAT INDUSTRIES

INESA has worked with different companies in the meat industry: slaughterhouses, cutting plants, processing undertaking, etc.

In the case of meat products (cold meats, sausages, hamburgers, etc.), the mincing and mixing of the emulsion in the mixer generates an increase in its temperature, damaging the good color and consistency of the product. These emulsion texture problems are due to the fact that the heat created by the mechanical work of the blade has an important effect on the size distribution of the fat particles. During the manufacture of vegetable products (sausages and veggie burgers, for example) these problems are more pressing, since hydrogenated vegetable fats are less suitable for emulsification than animal fats.

Flack ice mixed with the meat during the mincing operation, as a substitute for frozen water, avoids the overheating of the product, allows the maintenance of the temperature of the emulsion between 0 and 5 Cª throughout the manufacturing process and constitutes the moisturizer element of the preparation by helping to bind all the ingredients together. As it does not present sharp edges, the ice doesn’t deteriorate the meat, enveloping it and achieving maximum freshness and flavor retention.

The addition of flake ice, whose large exchange surface represents a high instantaneous contribution of refrigeration units, changes the density and improves the texture of the finished product. The resolution of the texture problems allows even better control of the weight of the product with a view to its final packaging.

For the manufacturing of cold cuts (for example, cooked ham), flake ice is used to keep shoulder and pieces of meat fresh before their cutting and processing. Freshness of ice-covered meat is preserved with the same method used for other perishable food products such as vegetables or fish.

Finally, in slaughterhouses and cutting plants flake ice is mixing with viscera to keep them at an adequate temperature.

AGRICULTURAL SECTOR

As soon as they are harvested, during transport and before being stored in cold rooms, fruits and vegetables are preserved in optimal conditions thanks to flake ice used in direct contact or, more commonly, mixed with cold water.

Ice machines pre-cool these products extracting the heat contained in the vegetable products during the harvest. Thanks to this method, metabolic processes and bacterial action are reduced, prolonging storage in warehouse and product freshness. Usually this cooling is carried out by placing flake ice between the layers of the product and an additional layer of ice on top of the box.

In the case of broccoli, it has a high respiration rate compared with other vegetables, and its commercial shelf life doesn’t exceed one and a half day when stored at 25ºC. Thanks to pre-cooling, at a ratio of 1 kg of flake ice per 4 kg of broccoli, most broccoli varieties maintain an acceptable quality between 10 and 14 days.